A step closer towards commercialization to fulfill brand demands

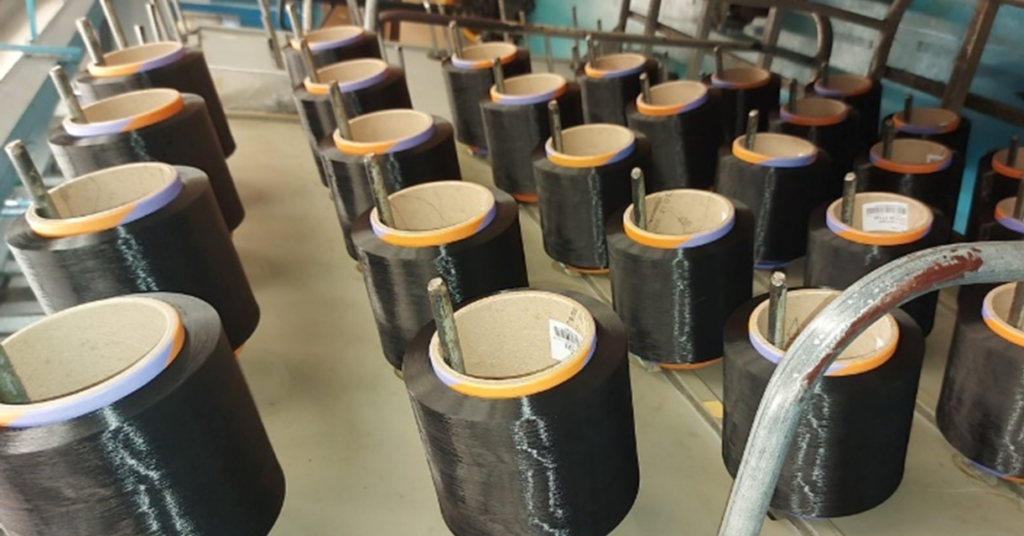

SAN DIEGO, California and Arco, Italy (July 20, 2022) —Sustainability leader Genomatica (Geno) alongside longtime collaborator Aquafil [ECNL:IM] successfully completed the first demonstration scale production runs for plant-based nylon-6. The material is intended to reshape the $22B nylon industry, enabling brands to meet demand from consumers for sustainable everyday materials from apparel to automotive parts to carpets. Geno and Aquafil have produced the first several tons of plant-based nylon-6 building block caprolactam, have converted it to nylon-6 polymer, and are now in the process of transforming it for evaluation in nylon applications such as yarns for textile and carpet and engineering plastics as part of pre-commercial quantities from demonstration production taking place in Europe.

The companies have been collaborating to first produce pilot-scale quantities of plant-based nylon-6 and have now advanced to produce pre-commercial quantities at demonstration scale which will help determine the final design of future commercial plants. The material will go to leading global brands and their value chain partners who are eager to explore and develop renewable products, create showcase goods and test feedback with customers.

“Now, more than ever, global brands are taking action to incorporate sustainable materials into their products,” said Christophe Schilling, Geno CEO. “We’re working to build purposeful, traceable and transparent supply chains, in this case for nylon 6, with the goal to provide more sustainable products that consumers demand and material solutions that can help brands achieve their ESG goals.

“The world needs every possible approach put into action to make supply chains sustainable, and making bio-based nylon an essential piece of that,” said Giulio Bonazzi, Aquafil CEO. “Plant-based nylon can perfectly complement our approach to depolymerizing nylon products once they reach the end of their useful life. Together, we share a vision to lead the transition to more sustainable materials which has driven our long-term collaboration.”

Plant-based nylon-6 is Geno’s third major product line on a path to commercialization. The company has executed high impact deals with a range of brands to accelerate the global commercialization of sustainable materials, with the potential to reduce greenhouse gas emissions by 100 million tons in upcoming years. Recent milestones advancing the sustainable materials transition include: a collaboration with lululemon (NASDAQ: LULU) to bring plant-based materials into lululemon’s products, a production milestone with partner Covestro (OTCMKTS: COVTY) for plant-based HMD used in sustainable coatings, and a partnership with Asahi Kasei (OTCMKTS: AHKSY) and a newly formed venture with Unilever (NASDAQ: UL) to commercialize and scale plant-based alternatives to feedstocks like palm oil or fossil fuels, to make key ingredients used in everyday cleaning and personal care products.

About Genomatica (Geno)

Geno is harnessing biology to remake everyday products and materials built by and for the planet. In response to the urgent climate crisis, Geno is developing and scaling sustainable materials derived from plant- or waste-based feedstocks instead of fossil fuels. Geno’s technology, built over the last 20 years, now drives materials and ingredients in applications ranging from cosmetics, carpets, to home cleaners, apparel and more.

To learn more, visit genomatica.com

About Aquafil

Founded in 1965, Aquafil is one of the main producers of nylon in Italy and worldwide. The Group is present in seven countries and in three different continents, with over 2,800 employees at 19 production sites located in Italy, Slovenia, United States, China, Croatia, Scotland, Thailand and Japan. Aquafil is a pioneer in the circular economy also thanks to the ECONYL® Regeneration System, an innovative and sustainable process able to create new products from waste and give life to an endless cycle. For more information, visit www.aquafil.com.

Media Contact

For Geno: Victoria Berryhill, genomatica@methodcommunications.com

For Aquafil: Maria Giovanna Sandrini, maria.giovanna.sandrini@aquafil.com

###